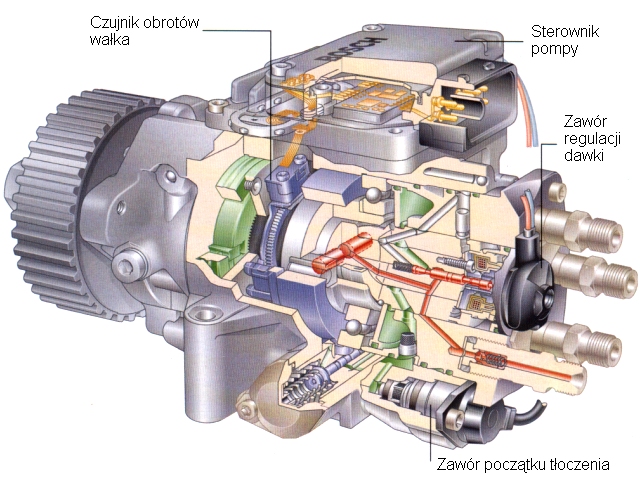

Construction and operation of the VP44 pump

Construction and operation of the VP44 pump

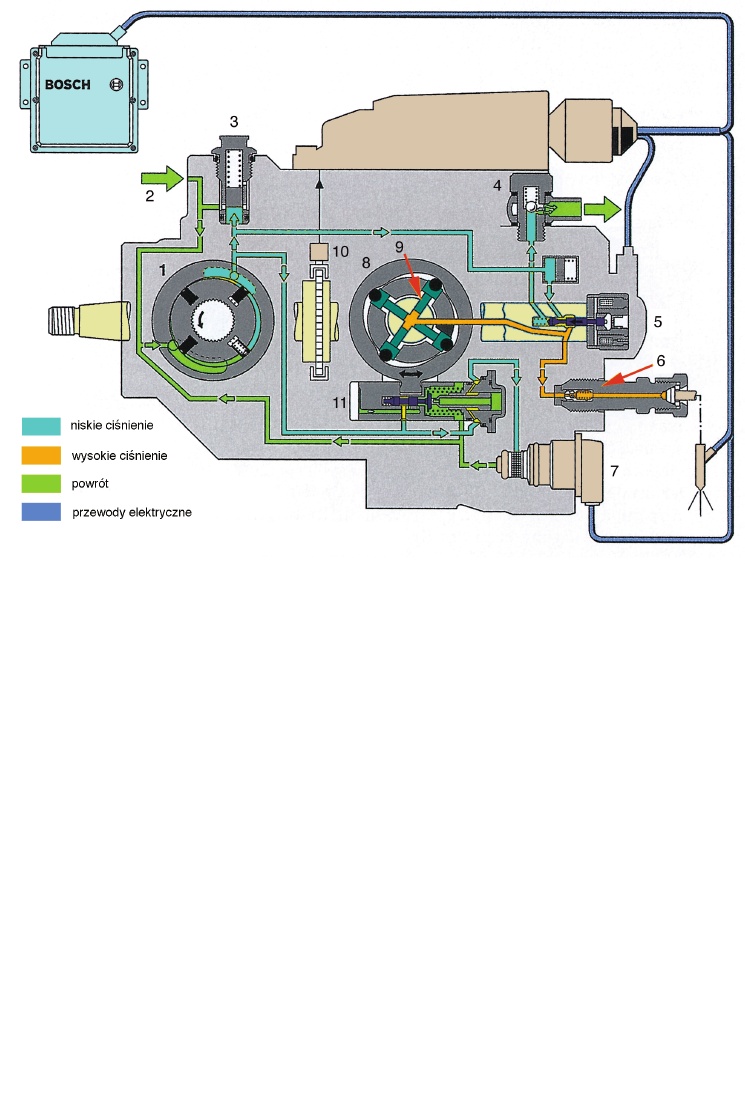

The radial distributor injection pump consists of a vane chamber pump with a pressure control valve and an overflow throttle valve. Its task is to suck fuel, building up pressure inside the hydraulic accumulator (Ok. 2,0 Mpa) and supplying fuel to the radial high pressure piston pump, which creates the high pressure necessary for fuel injection (to ok. 160 Mpa). The distributor shaft rotates with the high pressure pump, supplying fuel to individual cylinders. The high pressure solenoid valve is responsible for the fuel dose and is controlled by signals with variable pulse frequency by a controller located on the pump. The opening and closing of the valve determines the time of pumping fuel by the high pressure pump. Based on the signals of the rotation angle sensor (angular position of the shaft) the momentary angular position of the drive shaft and the cam ring relative to one another during rotation is established, calculated injection pump speed and (by comparison with the signals of the crankshaft sensor) detection position of the injection actuator setting. The angle of rotation sensor is located on a ring that rotates synchronously with the cam ring of the high pressure pump. The toothed dial of the pulse generator is located on the pump drive shaft. The toothless areas correspond to the number of engine cylinders.

A solenoid valve sets the position of the injection actuator, which turns the high pressure pump cam ring accordingly.

The figure shows schematically the internal structure of a radial distributor injection pump.

The figure shows schematically the internal structure of a radial distributor injection pump.

Injection start adjustment consists in comparing the signal from the nozzle needle lift sensor with the signal from the rotation angle sensor and on possible, change the position of the injection actuator accordingly.

The fuel enters the pump through the annular channel and flows through the open valve between the pistons. Precharge pressure causes, that the pistons are pressed against the cam ring.

Radial pumps (radial) they do not have – unlike axial pumps – springs pulling back the pistons. This is why, if the radial pump is operational, it can be turned by hand when disassembled. Difficulties when turning the shaft of the radial pump testify to this, that it is mechanically damaged.

When the distributor shaft turns, the follower rollers follow the curvature of the cam ring. The pistons are then pressed inward and compress the fuel to a high pressure. However, the delivery of fuel under high pressure then begins, when the solenoid valve is closed by a signal from the controller. The distributor shaft will position itself in front of the compressed fuel outlet to the appropriate cylinder. The fuel now flows through the throttle check valve and the connection through the hose to the injector, which, via a sprayer, injects them into the combustion chamber. The injection ends then, when the solenoid valve opens.