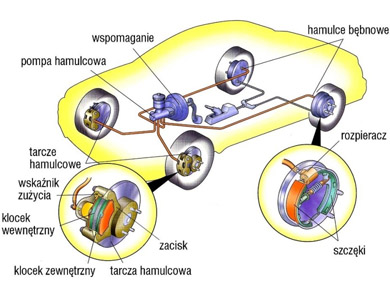

Brake actuating systems. Mechanical is used in motor vehicles, hydraulic or pneumatic brake actuators. The function of the brake actuation system is to transfer the muscular force of the driver or a force from a special energy source to the brake mechanism. Mechanical actuating system. Mechanically controlled braking systems are currently used in auxiliary brakes (hand held) and in the service brakes of motorcycles (rarely in small passenger cars). The disadvantage of the mechanical system is the difficulty of obtaining even braking of all wheels in the car. Incorrect adjustment or misadjustment of the brakes may, for example, cause. very strong braking of one wheel only and the throwing of the vehicle. Regulatory procedures are quite troublesome and have to be carried out quite often, due to the fairly frequent self-deflection of the brakes. Mechanical brake adjustment is made by adjusting the length of the rods with wing nuts or turnbuckles in this way, that pressing the brake pedal simultaneously presses the jaws of all wheels against the brake drums. Hydraulic actuation system. In modern cars, the so-called. hydraulic brakes, in which the force exerted by the driver on the pedal is transferred to the brake mechanism by means of a liquid called hydrol or brake fluid. Systems of this type are used in service brakes (footwear), that work on all wheels of the car. The advantage of hydraulic brakes is that all wheels are braked evenly as a result of this, that the pressure of the liquid spreads evenly in all directions. The brake actuation system consists of a brake pedal, brake pump, brake lines and hydraulic spreaders. The master cylinder with the brake fluid reservoir, when pressed on the pedal, pumps the fluid under pressure through rigid and flexible lines to the hydraulic cylinders, which in turn press the shoes against the brake drums. The condition for the efficient operation of the system is that it is completely filled with brake fluid. The presence of even small amounts of air prevents the brakes from working properly. A rupture of any of the hydraulic hoses also causes the braking system to malfunction, due to air in the system due to leakage of brake fluid. Brake fluid provided by CPN (Petroleum Products Headquarters) consists of the 40% castor oil and 60% butyl alcohol (by weight). It does not freeze in our climatic conditions, does not damage rubber, nor does it corrode metals. Please note, not to mix two different liquids, which can trigger a chemical reaction, as a result of which the elements of the master cylinder and hydraulic cylinders usually seize. Therefore, there should be only one type of brake fluid in the brake system. Rinse the brake system with denatured alcohol before adding any other fluid.

Brake actuating systems. Mechanical is used in motor vehicles, hydraulic or pneumatic brake actuators. The function of the brake actuation system is to transfer the muscular force of the driver or a force from a special energy source to the brake mechanism. Mechanical actuating system. Mechanically controlled braking systems are currently used in auxiliary brakes (hand held) and in the service brakes of motorcycles (rarely in small passenger cars). The disadvantage of the mechanical system is the difficulty of obtaining even braking of all wheels in the car. Incorrect adjustment or misadjustment of the brakes may, for example, cause. very strong braking of one wheel only and the throwing of the vehicle. Regulatory procedures are quite troublesome and have to be carried out quite often, due to the fairly frequent self-deflection of the brakes. Mechanical brake adjustment is made by adjusting the length of the rods with wing nuts or turnbuckles in this way, that pressing the brake pedal simultaneously presses the jaws of all wheels against the brake drums. Hydraulic actuation system. In modern cars, the so-called. hydraulic brakes, in which the force exerted by the driver on the pedal is transferred to the brake mechanism by means of a liquid called hydrol or brake fluid. Systems of this type are used in service brakes (footwear), that work on all wheels of the car. The advantage of hydraulic brakes is that all wheels are braked evenly as a result of this, that the pressure of the liquid spreads evenly in all directions. The brake actuation system consists of a brake pedal, brake pump, brake lines and hydraulic spreaders. The master cylinder with the brake fluid reservoir, when pressed on the pedal, pumps the fluid under pressure through rigid and flexible lines to the hydraulic cylinders, which in turn press the shoes against the brake drums. The condition for the efficient operation of the system is that it is completely filled with brake fluid. The presence of even small amounts of air prevents the brakes from working properly. A rupture of any of the hydraulic hoses also causes the braking system to malfunction, due to air in the system due to leakage of brake fluid. Brake fluid provided by CPN (Petroleum Products Headquarters) consists of the 40% castor oil and 60% butyl alcohol (by weight). It does not freeze in our climatic conditions, does not damage rubber, nor does it corrode metals. Please note, not to mix two different liquids, which can trigger a chemical reaction, as a result of which the elements of the master cylinder and hydraulic cylinders usually seize. Therefore, there should be only one type of brake fluid in the brake system. Rinse the brake system with denatured alcohol before adding any other fluid.