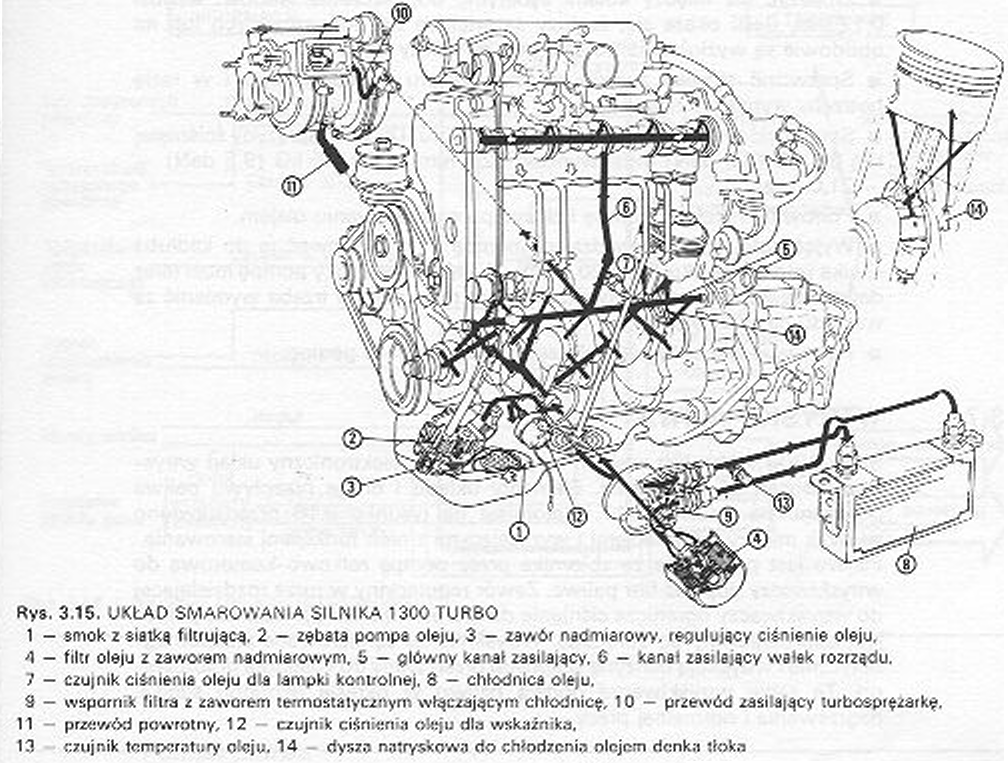

The lubrication system is powered by a gear pump located in the oil pan and driven by a toothed belt through an intermediate shaft (Lynx. 3.15).

The oil passes through the filter to the thermostatic control valve located in the filter support. Up to a temperature of 84 ° C, the oil is led directly to the bearing points. Above this temperature, the valve directs the oil to the radiator attached to the front of the car. There is an oil temperature sensor between the valve and the radiator. The oil through the spray nozzles additionally cools the piston crowns, and it is also fed to the turbocharger lubrication system.

The oil filter has a relief valve, which allows the oil to circulate when the filter element is clogged. Oil and filter should be changed every 7500 km due to high engine heat loads. Oil with the SF specification and SAE 15W / 40 viscosity grade may be used for replacement.

The oil pressure in the system is 3.4…4,9 bar at an oil temperature of 100ºC.

■ The oil pump can be removed from below after removing the oil pan.

■ Clamp the pump in a vice.

■ Disconnect the dragon from the housing.

■ Remove the intermediate plate.

■ Remove the pump wheels from the housing.

■ Clean and degrease all parts.

■ Fit the dry gears into the housing and use a feeler gauge to measure the play between wheels and housing. The play can be up to the maximum 0.18 Mm.

■ Measure the play between the sprockets; the allowed value is 0,12 Mm. If it turns out. that the clearances are greater than the allowable ones or there are grooves on the housing, the entire pump must be replaced.

■ Check the plunger of the relief valve for wear and replace the valve if necessary.

■ Check the valve spring characteristic. Length of the spring when compressed by force 8.8 medical history (8,8 and) must be 22,5 Mm, and by force 9,5 medical history (9.5 and) – 21,0 Mm.

■ Take the pump apart and reassemble it after lubricating it with oil.

■ Remove the gear wheel that drives the pump and attach it to the motor block (tightening torque 20 Nm). The shaft that drives the pump must now turn easily. Otherwise, the pump must be replaced due to a skew.

■ Reassemble the pump gear.